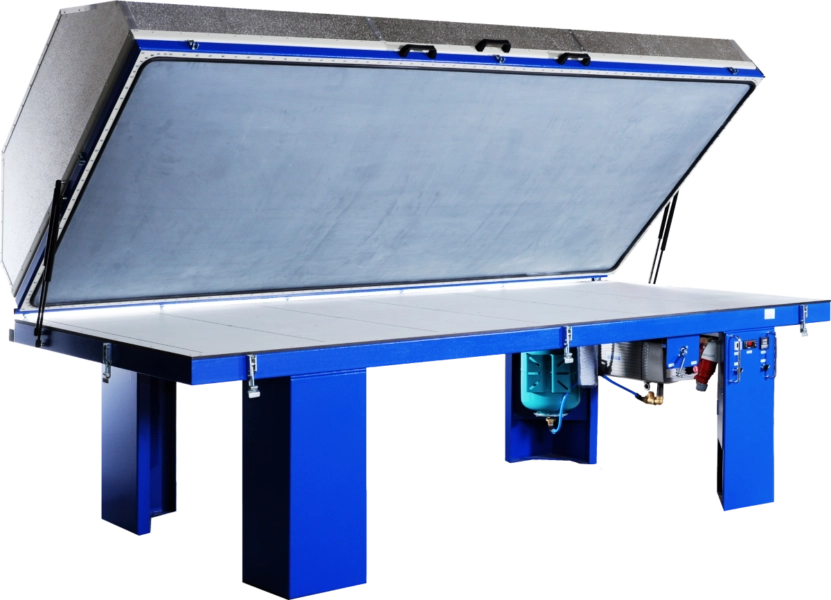

Bladder Vacuum Press – Innovative Solution for Veneering and 3D Forming.

Vacuum Veneering Press VPS is designed for 2D and 3D veneering as well as for wood bending. It is equipped with the heating system in the dome which is designed to greatly improve curing time of adhesives hence shorting loading intervals into the press.

VPS Press Works by Applying Pressure by the Membrane of 8 ton per m2.

Operations like veneering, bending panels, creating plywood curved chairs, rounded columns, intricate 3D elements are walk in the park. Heavy duty large table with fully welded steel elements provide you with ideal working environment for your production, prototyping and bouncing off ideas in the workshop.

Delivery

Warranty

What All Included In The Package

Some of the important features of the VPS MEMBRANE PRESS

With the durable steelwork you don't have to worry about anything you throw at our presses

Our working surface is designed for proper workshop projects

Even with our budget friendly VPS presses we are using 2mm silicon membranes - the same which we use for thermoforming presses.

They are very durable able to stretch 700% of their original size.

As our membranes are 2mm thick you can easily press chairs, curved wardrobe doors, apply leathers on wide curved panels and more.

We don't spare a penny - using famous Becker pumps for strong vacuum together with expansion vessel for rapid pressing times.

In seconds your elements will be pressed with 8ton per meter pressure.

Everyone from the fabrication trade had a situations where panels wasn't drying in -5 degree. Not anymore with our extra heating coils in the dome.

Your veneered panels literally ready in 15-20min to be taken out and process

We all know that time flies during work. That's why it's important to know exactly how long we had our panels during pressing or heating. By timer installed on control box you can be sure you will not miss your scheduled lenght of heating or pressing.

Designed for 1700kg of dynamic load on gantry – the whole CNC weights 1200kg so do not worry about any vibrations or movements.

Pneumatically operated bars and the 2 ends of the table to quickly lay down the boards exactly at the X=0 Y=0 position.

Technical Specification

- Working table dimensions (Model VPS3000AT): 2850 x 1150mm or 2850 x 1350mm (VPS3100AT)

- Silicone membrane 800% max temperature: 220

- Heater power: 5 kW

- Vacuum pump pressure: -0,75bar

- Vacuum pump output: 25 m3/h

- Operating vacuum: -0,85_0,90 kg/cm2 (bar)

- Protection code: IP53

- Noise level: < 70 Db

- Voltage: 3Phase 400 50Hz

- External dimension length: 3150mm

- External dimension width: 1350mm/1500mm

- External dimension height: 1600mm

- External dimension weight: 550 kg