Fabertec FL4

1530, 2030, 2040

Introducing the FABERTEC FL4 Fiber Laser, the ultimate solution for laser cutting subcontractors who demand unparalleled performance and reliability around the clock. With the FL4, you can process laser-cut parts non-stop, 24 hours a day, 7 days a week, ensuring maximum productivity and efficiency for your business.

Comparable to models from well-known brands that typically cost between £300k-800k, the FL4 Fiber Laser offers exceptional value starting from just £92k + VAT for the 6kW laser source configuration. Despite its affordable price point, the FL4 does not compromise on quality or capabilities.

Designed to operate as economically as possible, the FL4 boasts a robust construction and advanced features that enable it to handle a wide range of applications with precision and speed. From intricate designs to heavy-duty materials, the FL4 fiber laser delivers consistent and reliable results, allowing you to maximize the value of your investment.

Fabertec machines are compatible with all major metal fabrication software. Just export your design in DXF format and you’re ready to start cutting - no need to learn new systems.

BySoft

Lantek

Libellula

Sigmanest

TruTops

CAMduct

Maximizing Uptime, Efficiency, and Maintenance-Free Operations

FL4 maximizes uptime with an integrated shuttle table system, which allows one table to be loaded/unloaded while cutting on the other table. Table changeover is completed in just 45 seconds. Sheet edge recognition will adjust all your vectors to unaligned metal sheet on slats. Automatic height adjustment, laser head collision prevention and frog leap, will keep you cutting all day long without any stopovers. Micro Joint will allow you to cut tiny pieces, leaving a tab between elements to remove larger sections, instead of fishing out for small parts in floor drawer.

Fly cutting, circle centering, frame border and other are adding to efficiency in your operations Our fibre laser cutting machines are built to require little to no maintenance, and our laser sources may operate for up to 100,000 hours without calibration or expensive replacements. Only inexpensive spares, like lenses, lens covers, and nozzles, are needed. For businesses that need to create thousands of pieces in just a few days, fibre lasers for metal cutting are basically the only option.

The FL4 with a standard minimum table size of 1500 x 3000mm and a dual-table conveyor system, FL4 simplifies operations. Cut on one table while the second retracts, enabling easy sheet loading via forklift, magnetic crane, or clamp crane.

LASER SOURCE - THE HEART OF FIBER LASER CUTTING MACHINES

In all fiber laser cutting machines, the laser source is one of the most important parts that allows for smooth and accurate cuts. At FABERTEC we offer reliable and affordable MAX/RAYCUS laser sources.

Before 2024, we considered IPG as the go-to laser source, but after gaining in-depth training in laser source repairs and opening the first UK repair center, FABERTEC PHOTONICS, we’ve come to value MAX/RAYCUS brands with much more respect.

MAX/RAYCUS sources offer the same cutting quality, speed, and accuracy as higher-priced alternatives but at around 30–40% of the cost. What’s most important in our opinion is the fact that these affordable brands can be repaired with ease, spare parts are readily available, and they’re designed to be more open for local service centres. Of course, the final choice depends on your budget and preferences. At FABERTEC, we supply and install MAX or RAYCUS sources from our UK branch with full support.

⚠️ When cutting reflective materials like brass or copper, you must ensure the material is properly pierced to prevent bounce-back light from returning to the laser source. Damage caused by such reflections may not be covered by the manufacturer.

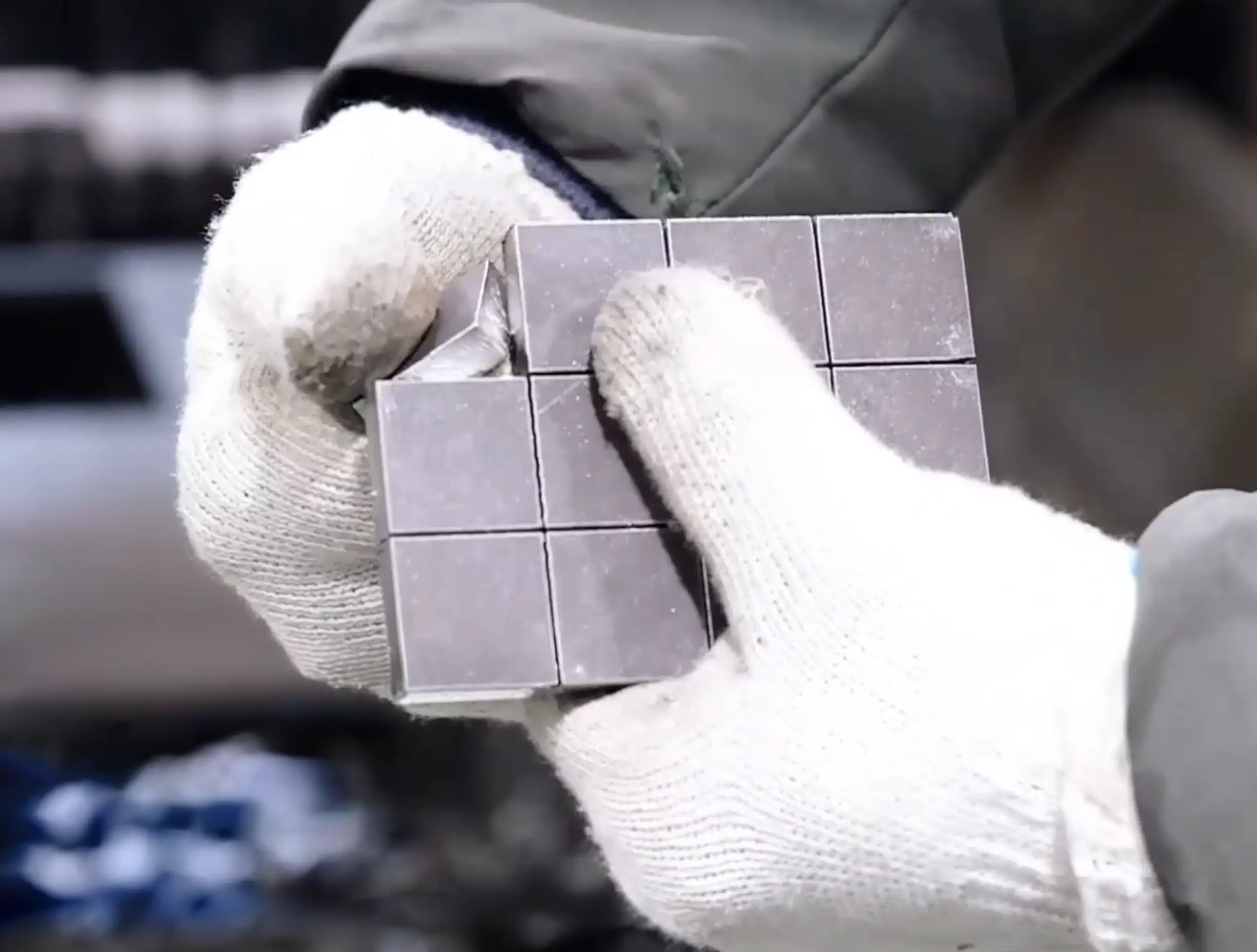

Fabertec Fiber Laser FL4 Build Quality

Parts or solutions we offer with every FL4 models

FSCUT CONTROLLER

The best “budget” controller in the world FSCUT 4000e/8000e used by tens of thousands of machines around the world. Same brand laser head and software to work in perfect unison.

BOCI 421/642 LASER HEAD

Same brand controller and software. Multiple safety sensors like temperature, pressure, and lens cleanliness to prevent damage and inform the operator well ahead of any problems.

DOUBLE SHUTTLE TABLE

Cut continuously without breaks to clean skeletons and parts. 45 seconds to exchange table, measure sheet angle, and cut the next sheet. Cut 100 sheets per day with ease.

FULL SAFETY BARRIERS

The rear table is protected by safety barriers. Protect your operators when exchanging tables.

CCTV CAMERAS

CCTV cameras inside the main body and rear table. The operator has a full view of what is happening in the machine and rear table.

DUST EXTRACTION

Fully sealed main body with extraction points to keep the machine and workshop clean and safe for employees. Additionally, below the table zones operate extraction points – focusing extraction where the laser head is cutting.

Smallest footprint in the industry. We know that space in UK workshops is worth a fortune.

LASER-RATED VISIBILITY SCREENS

Full visibility into the main body through laser-rated protection screens. They are designed to protect against the same wavelength of the laser as the machine is generating.

MAX LASER SOURCE

The most advanced laser source, very close in quality to IPG laser sources but at a fifth of the price. Fabricators no longer need to spend a fortune to accurately cut metal parts.

CYPCUT

Used by tens of thousands of operators on lasers around the whole world. Very easy to learn and cut in literally 30 minutes. Has all of the options to create vectors, leads, arrays, fly-cutting, sheet angle, nesting, micro joints, circle centering, countersink for screw heads, and many more.

Affordable prices to allow you to speed up your workshop processes.

| max laser | 6kw | 12kw | 20kw | 30kw |

|---|---|---|---|---|

| FABERTEC FL4 1530 | £92,000 | £150,000 | £185,000 | £220,000 |

| FABERTEC FL4 2030 | £122,000 | £180,000 | £215,000 | £250,000 |

| FABERTEC FL4 2040 | £137,000 | £195,000 | £230,000 | £265,000 |

| Metal Dust Extractor Filtered 2M | £6,000 |

| Metal Dust Extractor Filtered 4L | £9,000 |

| Metal Dust Extractor Filtered 6L | £12,000 |

| Metal Dust Extractor Filtered 8L | £14,000 |

| Spare Filter | £230 |

| Spare Valve | £150 |

Lease Purchase

| MODEL | TOTAL PRICE | MONTHLY | WEEKLY | DAILY |

|---|---|---|---|---|

| FL4 1530 6kW MAX | £92,000 + VAT | £2,071 | £478 | £68 |

NOTE: Figures shown for a 5-year lease term; VAT payable upfront.

VAT - Not included in the price above.

Dust Extractors Included - 4L for 6kW | 6L for 12kW | 8L for 20kW & 30kW

Have you ever wondered what makes the Fabertec fully enclosed double-table fiber laser cutter so affordable? Here's why:

Why Fabertec Fiber Lasers are so affordable?

Delivery

We provide free of charge delivery of the FL4 machine. On the Client side you will need forklift 5t-7t with 2000-2400mm forks (dependable on model) to unload and position in workshop.

After delivery, our engineers will visit the workshop to complete installation, commissioning, and training. This visit will be scheduled separately, based on the client’s availability and the engineer’s schedule.

Don't worry if on first day you may not be very fluent with all operations (most operators cut on their machines in about 1h). We will provide you with our WhatsApp number where engineers will help if stuck or doubt.

Warranty

- 5 Year Full Warranty (Parts, Labour, Source, Head & UK Support) included - for all new Fiber Laser Machines supplied from 1st June 2025 onwards.

- Obligatory maintenance visits every 12 months to keep your machine in top condition £1,500 + travel time (£85/h) + Fuel surcharge (£0.70/m)

- Machines supplied earlier continue under their original terms and conditions.

What is Included in the Package?

Fully assembled machine ready for work from our UK based workshops, all consumables like nozzles, lenses. Laser source and matching chillers. Demineralised water to fill your chiller on installation day. Lifetime software to draw and operate machine. Delivery on hiab, Installation and training. WhatsApp support to help operators with any issues.

LASER HEAD - THE "FOCUS" OF THE MACHINE

Dust Protection by Design

Smart and Safe Processing

Collision Screws

Protective Lenses Monitoring System

FL4 Controller Features

Envelope Check

Micro Joint

One-Path FlyCut

Up to 6KW

- Micro Joint – If you are cutting hundreds of small elements and not fancy digging them out from drawers – leaving a skeleton sheet with tiny tabs to remove, most of them, in one go.

- Scan to Import – Just scan your drawings to create vectors ready for cutting.

- Fast Piercing – Very effective for thinner sheets.

- Deslag – Improve quality on piercing by burning out slag. Especially important for thick plates.

- 5 Stage Piercing – Even more stages for very thick plates at the end of your laser source capability.

- Corner Technique – Improve quality on the sharp corners

- Quick Cutoff – Quickly cut off by pressing one button sheet edge on X or Y axis.

Fiber Laser Cutting Specification

| Material | MAX | 0.5mm | 1mm | 1.5mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm |

|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 1kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 1kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||

| STAINLESS STEEL | 1kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||

| BRASS | 1kW | ✔ | ✔ | ✔ | ✔ | ✘ | ||||

| COPPER | 1kW | ✔ | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm | 1mm | 1.5mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm | 12mm | 14mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 2kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 2kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||

| STAINLESS STEEL | 2kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||

| BRASS | 2kW | ✔ | ✔ | ✔ | ✔ | ✘ | |||||||

| COPPER | 2kW | ✔ | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm | 1mm | 1.5mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 3kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 3kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||||

| STAINLESS STEEL | 3kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||||

| BRASS | 3kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||||||

| COPPER | 3kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm - 5mm | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm | 22mm | 24mm | 26mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 4kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 4kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||||

| STAINLESS STEEL | 4kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||||||

| BRASS | 4kW | ✔ | ✔ | ✔ | ✘ | ||||||||

| COPPER | 4kW | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm - 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm | 22mm | 24mm | 26mm | 28mm | 30mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 6kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 6kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| STAINLESS STEEL | 6kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||||||

| BRASS | 6kW | ✔ | ✔ | ✔ | ✔ | |||||||||

| COPPER | 6kW | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm - 10mm | 12mm | 14mm | 16mm | 18mm | 20mm | 22mm | 24mm | 26mm | 28mm | 30mm | 32mm | 34mm | 36mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 8kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 8kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | |||||||

| STAINLESS STEEL | 8kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||||||||

| BRASS | 8kW | ✔ | ✔ | ✔ | ✘ | ||||||||||

| COPPER | 8kW | ✔ | ✔ | ✘ |

| Material | MAX | 0.5mm - 14mm | 16mm | 18mm | 20mm | 22mm | 24mm | 26mm | 28mm | 30mm | 38mm | 40mm | 42mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MILD STEEL | 12kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ |

| ALUMINIUM | 12kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ✘ | |||||

| STAINLESS STEEL | 12kW | ✔ | ✔ | ✔ | ✔ | ✔ | ✘ | ||||||

| BRASS | 12kW | ✔ | ✔ | ✔ | ✘ | ||||||||

| COPPER | 12kW | ✔ | ✔ | ✘ |

Please note: This document provides a general overview of the cutting parameters achievable with the MAX Laser Source. Areas marked in red represent "peak" performance for specific thicknesses. If your primary cutting requirements fall within the red range, it is advisable to consider upgrading your kilowattage to achieve improved performance and feed rates.

Some of the important features of the Fabertec FL4 Fiber Laser

Are you looking for a fully enclosed single table Fiber Laser machine?

Please consider Fabertec FL3 Fiber Laser Cutter

Technical specification

- Max/Raycus or German IPG laser source – advertised manufacturers fiber laser lifespan up to 100,000 hours – the equivalent of 10h daily cutting for 27 years!

- Structure fully welded and heat destressed

- Full servo motors Fuji or Yaskawa installed

- Speeds up to 80 meters per minute

- Aluminum reinforced gantry for higher speeds

- Hiwin runners with automatic lubrication

- Digital touch height control – laser head follows sheet height on the table (DTHC)

- Automatic height adjustment – laser heads follow sheet height on the table

- Automatic calibration – the controller automatically checks laser settings

- Large monitor with Cypcut software

- Handheld wireless control panel

- Draw, adjust, import DXF/PDF, create a lead in/out – all straight from the machine

- Two separate inlets for oxygen/nitrogen controlled by electric valves

- Automatic focus of laser head from software

- Supplied with array of nozzles, protective lenses, spares

- Runners and linear gear protection against laser and sparks possible damage

- Drawers underneath the table for offcuts/parts

- Two automatic tables installed

- Supplied with powerful chiller also with the heating option – in case workshop temperature goes below 0 to prevent damage from water freezing

- Optional dust extractors with fire protection to keep the warehouse free from metal dust

- Single phase (230v) up to 2kw laser source